The global Medium-Density Fibreboard (MDF) Market Size has seen significant growth in recent years, driven by the increasing demand from various industries, including furniture, construction, and interior design. The market is expected to continue growing at a robust rate, with the global MDF market reaching an estimated value of USD 30.85 billion in 2024. Projections indicate that the market will further expand at a compound annual growth rate (CAGR) of 8.90% from 2025 to 2034, eventually reaching USD 72.37 billion by 2034.

Market Overview

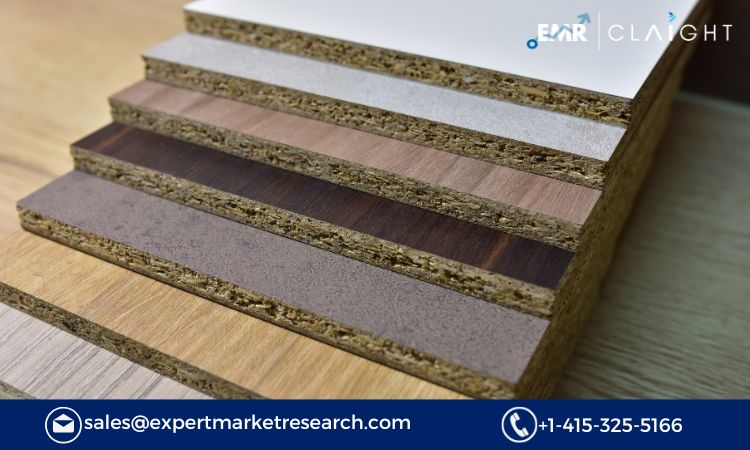

Medium-density fibreboard (MDF) is a popular engineered wood product made from wood fibers, wax, and resin, which are combined under heat and pressure to create a dense, durable material. MDF offers superior qualities such as smooth surfaces, high flexibility, and ease of machining, making it ideal for a variety of applications in furniture manufacturing, cabinetry, flooring, and decorative designs. Its versatility and cost-effectiveness have positioned MDF as an essential material in construction and interior design projects.

Key Benefits of MDF

The growing popularity of MDF can be attributed to the various advantages it offers over traditional solid wood products:

-

Smooth and Consistent Surface: MDF’s smooth surface allows for excellent finishing, making it ideal for painting, veneering, or laminating. Unlike solid wood, MDF does not have natural knots or grains, ensuring a smooth and uniform texture across the board.

-

Cost-Effective: MDF is relatively more affordable than solid wood or plywood, which makes it an attractive option for cost-conscious consumers in construction and furniture industries.

-

Ease of Workability: MDF can be easily cut, shaped, and molded into complex designs, offering greater design flexibility for architects, designers, and manufacturers.

-

Environmental Sustainability: Many manufacturers of MDF use recycled wood fibers, reducing the demand for raw timber and promoting environmental sustainability. The ability to utilize wood waste further reduces the ecological footprint of MDF production.

-

Strength and Durability: While MDF is not as strong as solid wood, it provides a reasonable balance of strength and durability for most applications, particularly in furniture and interior design.

-

Soundproofing Properties: Due to its density and structure, MDF has excellent sound-dampening properties, making it ideal for use in the construction of acoustic panels, doors, and flooring solutions.

Market Segmentation

The MDF market can be segmented based on product type, end-user industry, and region. These segments provide a comprehensive understanding of the market’s growth prospects and opportunities.

-

By Product Type:

- Standard MDF: This is the most commonly used form of MDF. It is often used in furniture and interior décor.

- Moisture-Resistant MDF: Ideal for areas exposed to moisture such as kitchens and bathrooms, this type of MDF resists swelling and degradation.

- Fire-Retardant MDF: Used in applications where fire safety is a concern, such as in commercial and public buildings.

- Flexible MDF: Suitable for applications where the material needs to be bent or curved, such as in the creation of intricate designs and furniture.

-

By End-User Industry:

- Furniture Industry: The furniture industry is the largest consumer of MDF. MDF is used to manufacture furniture pieces such as cabinets, tables, and chairs due to its cost-effectiveness and ease of finishing.

- Construction & Building: MDF is extensively used in the construction industry for creating partitions, doors, wall panels, and flooring. Its ease of installation and versatility in design make it ideal for modern buildings.

- Automotive: In the automotive industry, MDF is used for manufacturing components like dashboards and door panels due to its durability and lightweight properties.

- Packaging: The packaging industry also uses MDF for creating strong, durable packaging solutions for goods that require secure handling.

-

By Region:

- North America: The North American market is expected to see continued growth due to the rising demand for sustainable and cost-effective materials in the construction and furniture industries.

- Europe: Europe remains a major market for MDF, driven by the increasing preference for eco-friendly building materials and the presence of a robust furniture manufacturing industry.

- Asia-Pacific: The Asia-Pacific region is anticipated to witness the highest growth rate in the coming years, largely driven by rapid urbanization, infrastructure development, and an expanding middle class.

- Latin America: The Latin American MDF market is expected to grow as construction and interior design activities continue to rise in countries like Brazil and Mexico.

- Middle East & Africa: This region’s market growth is primarily driven by the increasing demand for residential and commercial construction and a rise in demand for MDF in the furniture sector.

Key Industry Developments

Several developments are shaping the MDF market, from innovations in product technology to the increasing demand for sustainability:

-

Technological Advancements: The market is witnessing the development of advanced MDF boards, such as fire-retardant and moisture-resistant MDF, driven by the need for specialized applications in the construction and furniture industries.

-

Sustainability Trends: Manufacturers are increasingly adopting sustainable practices, such as using recycled wood fibers and low-emission adhesives to produce eco-friendly MDF products. This aligns with the growing demand for green building materials in construction.

-

Expansion of Production Capacity: Several leading MDF manufacturers are expanding their production capacities to meet the increasing demand for MDF in emerging markets. Investments in automated manufacturing processes are also improving efficiency and product quality.

-

Collaborations and Mergers: Major players in the MDF market are entering into partnerships, mergers, and acquisitions to strengthen their market presence and expand their product portfolios.

Driving Factors for the MDF Market

Several key factors are contributing to the continued growth of the MDF market:

-

Urbanization and Infrastructure Development: Rapid urbanization and large-scale infrastructure development in emerging economies, particularly in Asia-Pacific, are driving the demand for MDF in both residential and commercial construction.

-

Rising Disposable Income: The increasing disposable income of the middle class in developing countries is fueling demand for stylish and cost-effective furniture and home décor, which is further increasing the demand for MDF.

-

Growth in the Furniture Industry: The demand for affordable, durable, and eco-friendly materials for furniture manufacturing continues to increase, providing a boost to the MDF market.

-

Environmental Concerns: The growing focus on sustainability is driving the use of eco-friendly materials, with MDF being a key component due to its lower environmental impact compared to traditional wood products.

COVID-19 Impact

The COVID-19 pandemic had a profound impact on the global MDF market. During the initial stages of the pandemic, production and supply chain disruptions affected the manufacturing and delivery of MDF products. However, as the world began to recover, demand for MDF rebounded, particularly in the furniture and construction sectors, as governments initiated infrastructure projects and residential construction activities surged.

Restraining Factors

Despite the significant growth prospects, the MDF market faces several challenges:

-

Raw Material Prices: Fluctuations in the prices of raw materials, such as wood fibers and resins, can impact the cost of MDF production and make it less competitive compared to alternative materials like plywood.

-

Environmental Regulations: Stringent environmental regulations regarding the use of certain chemicals and adhesives in MDF production can increase production costs for manufacturers, potentially limiting market growth.

-

Competition from Alternatives: The growing availability of alternative engineered wood products, such as particleboard and plywood, poses a challenge to the MDF market. These products offer similar benefits at often lower prices.

Major Key Players in the MDF Market

- EGGER Group

- Norbord Inc. (West Fraser)

- Kronoplus Limited

- Financiera Maderera S.A. (FINSA)

- Daiken Corporation

- Fantoni Spa

- Duratex S.A.

- ARAUCO

- SWISS KRONO TEX GmbH & Co. KG

- Others

Opportunities

The MDF market presents numerous opportunities:

-

Growth in Emerging Markets: As urbanization accelerates in emerging economies, the demand for MDF is expected to increase substantially. Countries like India, China, and Brazil offer significant opportunities for MDF manufacturers.

-

Sustainable MDF Products: There is a growing demand for sustainable building materials. Companies that invest in producing environmentally friendly MDF, such as low-VOC (volatile organic compound) or formaldehyde-free options, can gain a competitive edge.

-

Technological Innovation: Advancements in manufacturing technology, such as the use of digital technologies in design and production, can help manufacturers improve product quality, reduce costs, and enhance efficiency.

Challenges

The MDF market faces several challenges that could hinder its growth:

- Raw Material Shortages: The scarcity of high-quality wood fibers can constrain the production of MDF, impacting the overall supply chain.

- Environmental Impact: Despite being more sustainable than solid wood, MDF production still involves chemicals and adhesives that can have environmental impacts if not managed properly.