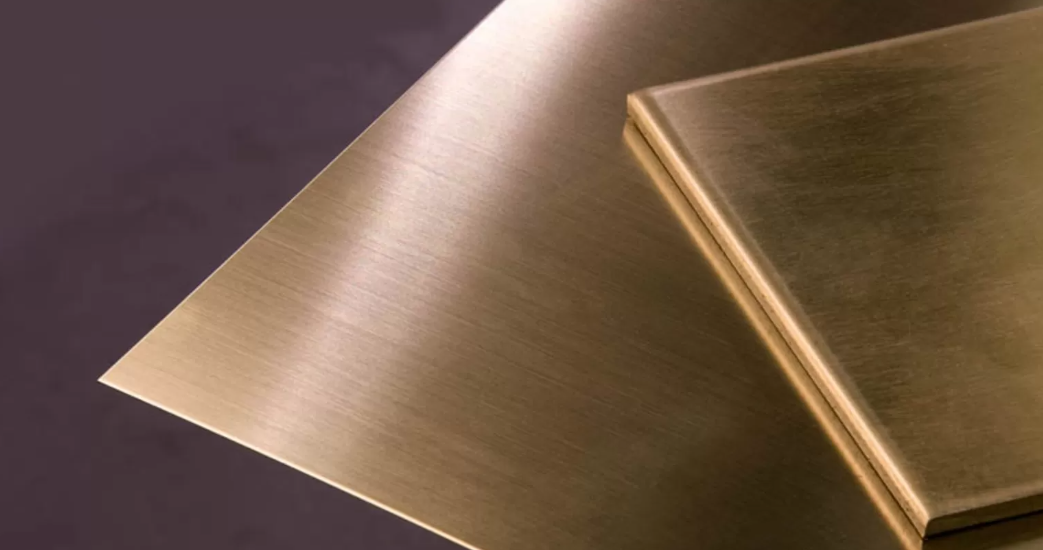

Phosphor Bronze is a widely used alloy known for its excellent mechanical properties, corrosion resistance, and durability. Composed primarily of copper with small amounts of tin and phosphorus, Phosphor Bronze Sheets are extensively utilized in various industrial applications where strength, wear resistance, and electrical conductivity are essential. In this article, we will explore the key properties and industrial uses of Phosphor Bronze Sheets.

Key Properties of Phosphor Bronze Sheets

1. High Strength and Durability

Phosphor Bronze is recognized for its superior tensile strength and toughness, making it an ideal material for heavy-duty applications. The addition of tin enhances its hardness, while phosphorus improves its wear resistance and fatigue strength.

2. Excellent Corrosion Resistance

One of the most important attributes of Phosphor Bronze Sheets is their high resistance to corrosion, particularly in marine and industrial environments. They are highly resistant to chemical exposure, moisture, and atmospheric conditions, making them suitable for outdoor and harsh applications.

3. Good Electrical Conductivity

While not as conductive as pure copper, Phosphor Bronze still retains good electrical conductivity. This makes it a preferred material in the electrical and electronics industry for connectors, switch components, and circuit board springs.

4. Low Coefficient of Friction

Phosphor Bronze exhibits a low coefficient of friction, which means it reduces wear and tear when used in moving parts. This property makes it highly suitable for bearings, bushings, and gears that require long-lasting performance with minimal maintenance.

5. Superior Wear and Fatigue Resistance

The alloy’s unique composition enhances its resistance to fatigue and wear, making it ideal for applications that require repetitive stress and movement. This property is particularly valuable in the manufacturing of industrial springs and fasteners.

Industrial Applications of Phosphor Bronze Sheets

1. Electrical & Electronics Industry

- Used in electrical connectors, contacts, and terminals due to its excellent conductivity and resistance to corrosion.

- Ideal for circuit board springs and relays in electronic devices.

2. Marine Applications

- Resistant to seawater corrosion, making it a preferred material for marine hardware and shipbuilding components.

- Used in propellers, fasteners, and underwater fittings.

3. Automotive Industry

- Applied in transmission components, valve guides, and bushings due to its wear resistance and durability.

- Used in electrical wiring and connectors in vehicles.

4. Aerospace Industry

- Ideal for aerospace bushings and bearings, ensuring longevity in high-stress environments.

- Utilized in aircraft fasteners and structural components for lightweight strength.

5. Industrial Machinery & Equipment

- Found in gears, bearings, and industrial springs that require high fatigue strength and low friction.

- Used in conveyor systems and mechanical couplings.

6. Musical Instruments

- Applied in the manufacturing of guitar strings, wind instruments, and percussion hardware due to its resonance and durability.

7. Chemical Processing Industry

- Used in chemical-resistant equipment, including storage tanks and processing units, due to its corrosion resistance.

Conclusion

Phosphor Bronze Sheets offer a unique combination of strength, corrosion resistance, and electrical conductivity, making them indispensable in various industrial sectors. Whether used in electrical components, marine equipment, or heavy-duty machinery, Phosphor Bronze proves to be a reliable and long-lasting material. For industries requiring high-performance materials, Phosphor Bronze Sheets remain a preferred choice for their outstanding properties and wide-ranging applications.